Pilot Operated Blanketing Regulators (Model D950)

are available for high flow and low pressure requirements.

Blanketing Pressure Regulator (Inbreathing Regulator) D 300

Back Pressure Regulating Valve (Depadding Regulator) – U300

Pressure Vacuum Relief Valve ie Breather Valve

Flame Arrestors

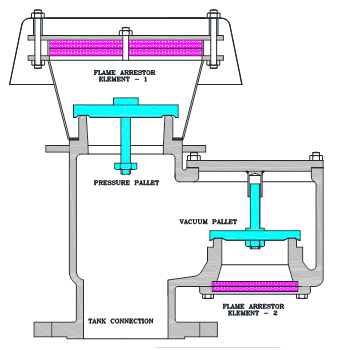

Breather Valve With Built-In Flame Arrestor – B900

Emergency Vent Valve – E100

Blanketing Application : Specially designed for use in corrosive as well as non corrosive atmospheres like chemical and pharmaceuticals for inertization of storage tanks, centrifuges, reactors and vessels. Being compact and inlet from bottom makes the installation easy and economical.

Accurate low pressure regulation : Lever type construction transmits diaphragm movement into precise orifice opening even at very low pressure giving constant fuel gas supply to burners, gas trains, furnace etc.

Easy Maintenance : Unique design facilitates easy and fast maintenance & inspection of regulator internals.

Appropriate material range : Variety of material is available to suit corrosive solvents stored in vessels and for various utility gases. Also, available with NACE compatible material for sour gas applications.

Tamper - Resistant Adjustment : Cap and adjusting screw discourage on-field tampering of the pressure setting.

Load absorbing Diaphragm assembly : Special load absorbing diaphragm assembly prevents diaphragm failure during malfunctioning thus providing safety against leakage of fluid to atmosphere.

Wide set range for various applications : Design is compatible for various set pressures between 50 mmWC till 750 mBar for various applications and process requirements.

Bulit In Flame Arrestor: Construction of the unit is such that the Flame Arrestors are provided on the Pressure Vacuum Relief Valve body itself.

Separate Flame Arrestors for each port : Pressure Relief Port as well as the Vacuum Relief Port is equipped with separate Flame Arrestor each.

Cleaning of Flame Arrestor Element : Cleaning of Flame Arrestor Elements is easy and less time consuming and can be done without removing the unit from the tank nozzle.

Easy Maintenance : The maintenance and inspection of the pressure and vacuum pallets is easy and less time consuming.

Soft Seated Design : Combination of metallic and soft seating enhances performance at low set values and reduces the leak rate.

Material selection : As a standard we provide trim material as AISI 316. Wide range of material is available to suit various services for different process fluids including corrosive fluids. NACE compliance can be provided for sour services.

Minimum Maintenance Cost : The general replacement parts are polymer parts like Diaphragm Seals and Gaskets only and thus the maintenance cost is very low.

Back Pressure Regulation / Control : These are designed to respond to the smallest rise in pressure at inlet and allow the excess pressure at outlet affecting protection of equipments like storage tanks and process vessels. These are also used as Pressure Holding Valves as they hold the pressure at upstream.

Self Actuated Design : This series of back pressure regulating valves are self actuated or self contained and hence, do not require any external energy like pneumatic air or electricity to operate.

Internal impulse Sensing : The impulse sensing is internal ie through the valve body itself avoiding the impulse tubing for sensing.

Accurate Pressure Control : The inlet pressure directly acts on the diaphragm to counter balance the spring force affecting efficient response capability and accuracy.

Easy Maintenance : The maintenance and inspection of the back pressure regulating valve internals is possible without removing body from pipe line.

Material selection : As a standard we provide trim material as AISI 316. Wide range of material is available to suit various services for different process fluids including corrosive fluids. NACE compliance can be provided for sour services.

Tamper - Resistant Adjustment : Cap and adjusting screw discourage on-field tampering of the pressure setting.

Leakage Proof : Combination of metallic and soft seat enables the leakage class VI as per ANSI FCI 70.2.

Minimum Maintenance Cost : The general replacement parts are polymer parts like Diaphragm, Soft Seat & O Rings only and thus the maintenance cost is very low.

REGPORT Flame Arrestors are designed with Crimped Metal Ribbon design, which ensures least pressure drop and has better life with ease of cleaning. Also, these are replaceable and can be changed at site.

Dead Weight Type Design : As a standard, upto a certain set pressure, Dead Weight Type Emergency Vent Valve is designed and supplied.

Spring Loaded Type Design : Depending on higher set pressure requirements, spring loaded type Emergency Vent Valve is designed and supplied.

Precise Pressure Relief : The precisely designed dead weight / springs ensue to achieve precise pressure relief at set values.

Bubble Tight Seat Leakage : Bubble Tight Shut Off is ensured at operating pressures and upto 90% of set pressures so that no loss of Vapors / Nitrogen is ensured during normal operating conditions.

Special Design Air Cushioning Diaphragm : The Special “air cushioning” diaphragms are constructed of Teflon (with Neoprene / BunaN cushion) to ensure Bubble Tight Shut Off.

Teflon Diaphragms : Contribute to high resistance to adhesion of ice and gum formation caused by combination of atmospheric moisture and resinous vapors. This assures protection against pallet sticking to the seating surface.

Central Guiding : The vertical central guiding system ensures the proper alignment of seating surface and maximum lift of pallet provides maximum flow.

Material selection : As a standard we provide trim material as AISI 316. Wide range of material is available to suit various services for different process fluids including corrosive fluids. NACE compliance can be provided for sour services.

Ease in installation and handling : Emergency Vent Valves are easy to install and convenient for handling

Minimum Maintenance Cost : The general replacement parts are polymer parts like Diaphragm Seals and Gaskets only and thus the maintenance cost is very low.