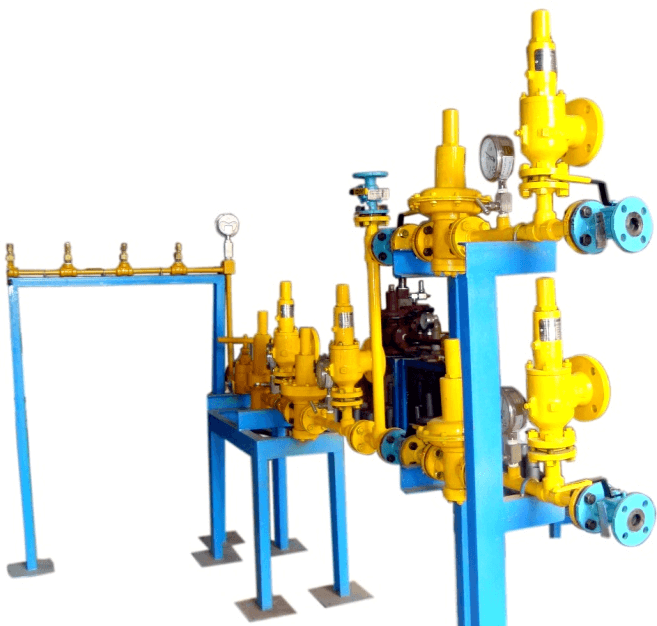

High Pressure Reducing Station

High Pressure Reducing Station

Specific Features and Configurations

Hydrogen Manifold and Pressure Reducing System.

For Hydrogen Gas

The Manifold and components at inlet of Pressure Regulating Systemsupto outlet of first stage reduction are designed for Inlet Pressure upto 210 Barg.

Non Venting Safety ie Slam Shut Off Valves to avoid the over pressure at outlet of first stage regulators are offered to cut down the gas supply in the event of passing at first stage regulator seating.

Safety Relief Valves alongwith Flame Arrestors are offered at outlet of each Pressure Regulator.

Non Return Valve with Lift Check design is offered at outlet of each Pressure Regulating System.

Pressure Reduction in minimum two stages or three stages or with multiple streams for various pressure requirements at different applications.

For Nitrogen Gas

The Manifold and components at inlet of Pressure Regulating Systems upto outlet of first stage reduction are designed for Inlet Pressure upto150Barg.

Safety Relief Valves are offered at outlet of each Pressure Regulator.

Pressure Reduction in minimum two stages or with multiple streams for various pressure requirements at different applications like purging, material transfer etc.

Nitrogen Manifold and Pressure Reducing System

Intermediate Pressure Regulating Systems for various gases like Nitrogen, Hydrogen, Air, Oxygen, Ammonia etc

Suitable configuration like twin stream or single stream with by-pass or only single stream with inlet outlet isolation are proposed based on applications.

Adequate Filtration with Strainer or Filter

Safety Relief Valves (alongwith Flame Arrestors as per process safety requirements) at outlet of each Pressure Regulator.

Oil Cleaning and De-greasing for services like Oxygen Gas