Pressure Regulation

Self Actuated Pressure Control Valves

REGPORT Self Actuated Pressure Control Valves, also referred as SAPCV are tailor made to the requirement of our customers present in all industrial segments. These Self Actuated Pressure Control valves have an edge over conventional control valves as these do not require any auxiliary inputs like pneumatic line, electricity or hydraulic line. These SAPCV operate on the basis of signal received from line fluid itself. Generally, a control valve comprises of a sensor, controller and the final controlling device as a minimum.

All these three functions are integrated in single equipment of SAPCV and hence, this is self contained unit for the precise pressure control. These SAPCVs use feedback of the regulated pressure as input signal (either from Upstream or Downstream) to the control mechanism. The control mechanism is either Diaphragm or Piston actuated by Spring. Based on this feedback the SAPCV controls the process.

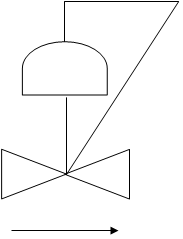

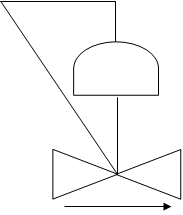

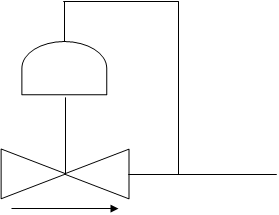

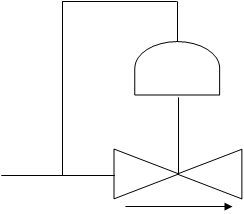

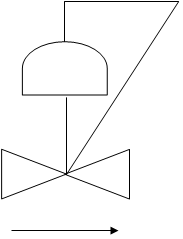

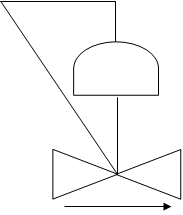

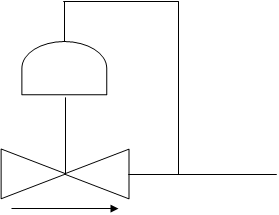

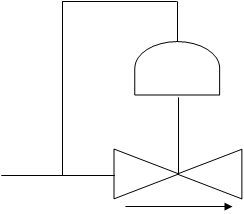

Typical Symbols of Self Actuated Pressure Control Valves

Self Actuated Pressure Control Valve Direct Acting – Downstream

Self Actuated Pressure Control Valve Direct Acting – Upstream

Self Actuated Pressure Control Valve Pilot Operated – Downstream

Self Actuated Pressure Control Valve Pilot Operated – Upstream

REGPORT Self Actuated Pressure Control Valves, also referred as SAPCV are tailor made to the requirement of our customers present in all industrial segments. These Self Actuated Pressure Control valves have an edge over conventional control valves as these do not require any auxiliary inputs like pneumatic line, electricity or hydraulic line. These SAPCV operate on the basis of signal received from line fluid itself. Generally, a control valve comprises of a sensor, controller and the final controlling device as a minimum. All these three functions are integrated in single equipment of SAPCV and hence, this is self contained unit for the precise pressure control. These SAPCVs use feedback of the regulated pressure as input signal (either from Upstream or Downstream) to the control mechanism. The control mechanism is either Diaphragm or Piston actuated by Spring. Based on this feedback the SAPCV controls the process.

Typical Symbols of Self Actuated Pressure Control Valves

SELF ACTUATED PRESSURE CONTROL VALVE DIRECT ACTING – DOWNSTREAM

SELF ACTUATED PRESSURE CONTROL VALVE DIRECT ACTING – UPSTREAM

SELF ACTUATED PRESSURE CONTROL VALVE PILOT OPERATED – DOWNSTREAM

SELF ACTUATED PRESSURE CONTROL VALVE PILOT OPERATED – UPSTREAM

The basic working principle for this DA-SAPCV is force balanced principle achieved by spring diaphragm mechanism. The fluid pressure acts on the wider area of diaphragm and the balancing force is provided by the spring. Thus fluid force itself is an operating media and the best control is achieved even for the smallest deviation in controlled parameter as its (fluid force) acting on the wider area of diaphragm.

D100 Series :- Downstream Pressure Control Valve

Direct Acting Downstream Pressure Regulating Valves – also, called as Pressure Reducing Valves – are meant for reducing the source pressure and regulating the outlet / downstream pressure at the pre-determined set value required for the processes. With direct acting Regulators precise pressure control can be achieved at specified process requirements.

As outlet / downstream pressure tend to drop due to consumption at process, the spring force pushes the diaphragm down, due to which stem & soft seating disc also moves down and opens the port. As soon as outlet / downstream pressure is compensated, the diaphragm pushes up, the stem & soft seating disc also moves up and the port opening closes.

As outlet / downstream pressure tend to drop due to consumption at process, the spring force pushes the diaphragm down, due to which stem & soft seating disc also moves down and opens the port. As soon as outlet / downstream pressure is compensated, the diaphragm pushes up, the stem & soft seating disc also moves up and the port opening closes.

FEATURES

This series of pressure regulating valves are self actuated or self contained and hence, do not require any external energy like pneumatic air or electricity to operate.

The precise outlet pressure control is achieved with this design affecting efficient response capability and accuracy.

Due to balanced trim design, the variation in outlet pressure due to change in inlet pressure is minimal.

The maintenance and inspection of the pressure regulating valve internals is possible without removing body from pipe line.

As a standard we provide trim material as AISI 316. Wide range of material is available to suit various services for different process fluids including corrosive fluids. NACE compliance can be provided for sour services

Cap and adjusting screw discourage on-field tampering of the pressure setting.

Special load absorbing diaphragm assembly prevents diaphragm failure during heavy load

Combination of metallic and soft seat enables the leakage class VI as per ANSI FCI 70.2.

The general replacement parts are polymer parts like Diaphragm, Soft Seat & O Rings only and thus the maintenance cost is very low.

The change in set pressure can easily be achieved by turning the set screw at site. Also, a wide range can be availed with the certain spring and in case, if needed, the spring can be changed at site for achieving desired set pressure with certain limitation.

MATERIAL OF CONSTRUCTION

CS A216 Gr WCB (standard), CF8, CF8M, Aluminium, CF3, CF3M, WC6, WC9, LCB, LCC, AlumBronze, Monel, Inconel or any other material on request.

St St316 (standard), St St304, 316L, Monel, Inconel, Hastelloy B/C or any other material on request

BunaN (Nitrile), Neoprene, Fluroelastomer (Viton), PTFE or any other material suitable for process / on request

Reinforced Polymers like Buna N (Nitrile), Neoprene, Fluroelastomer (Viton), and PTFE with polymer backup

SS302, SS316, Inconel X750 or any other material on request.

Carbon Steel IS4454 Gr.II / III, H12, EN47, SS302, SS316, Inconel X750 or any other material on request.

Fabricated Steel (Standard) and other on request

The basic working principle for PO-SAPCV is force balance only. However, this is meant for the fine and precise pressure control when flow requirement is high. The pilot valve basically is a direct acting SAPCV only. The fluid from pilot and the main line acts on either side of the main valve actuator diaphragm resulting in the most precise reading of deviation in the controlled parameter and in turn the best performance for pressure control.

The SAPCV, which monitors and controls the inlet pressure irrespective of variations in outlet pressure and flow rate are called as upstream pressure control valves. These are meant for controlling the inlet pressure at a precise set value or hold the line pressure or back pressure at its inlet and hence, often called as Pressure Holding Valve or Back Pressure Regulating Valves as well.

The U100 Series are Direct Acting Self Actuated Globe Type Medium Pressure Back Pressure Regulating Valves meant to regulate the inlet pressure at the pre-determined set value required for the processes / equipment protection.

As inlet / upstream pressure tend to rise, it pushes the diaphragm up, the stem & soft seat disc also moves up, an opens the port and relief the excessive pressure. As inlet / upstream pressure is compensated the spring force pushes the diaphragm down, the stem & soft seat disc also moves down and port opening closes affecting stoppage of flow.

The U100 Series are Direct Acting Self Actuated Globe Type Medium Pressure Back Pressure Regulating Valves meant to regulate the inlet pressure at the pre-determined set value required for the processes / equipment protection.

As inlet / upstream pressure tend to rise, it pushes the diaphragm up, the stem & soft seat disc also moves up, an opens the port and relief the excessive pressure. As inlet / upstream pressure is compensated the spring force pushes the diaphragm down, the stem & soft seat disc also moves down and port opening closes affecting stoppage of flow.

FEATURES

his series of pressure regulating valves are self actuated or self contained and hence, do not require any external energy like pneumatic air or electricity to operate.

The precise inlet pressure control is achieved with this design affecting efficient response capability and accuracy.

The maintenance and inspection of the pressure regulating valve internals is possible without removing body from pipe line.

As a standard we provide trim material as AISI 316. Wide range of material is available to suit various services for different process fluids including corrosive fluids. NACE compliance can be provided for sour services.

Cap and adjusting screw discourage on-field tampering of the pressure setting.

Special load absorbing diaphragm assembly prevents diaphragm failure during heavy load.

Cap and adjusting screw discourage on-field tampering of the pressure setting.

Combination of metallic and soft seat enables the leakage class VI as per ANSI FCI 70.2.

The general replacement parts are polymer parts like Diaphragm, Soft Seat & O Rings only and thus the maintenance cost is very low.

The change in set pressure can easily be achieved by turning the set screw at site. Also, a wide range can be availed with the certain spring and in case, if needed, the spring can be changed at site for achieving desired set pressure with certain limitation.

MATERIAL OF CONSTRUCTION

CS A216 Gr WCB (standard), CF8, CF8M, Aluminium, CF3, CF3M, WC6, WC9, LCB, LCC, AlumBronze, Monel, Inconel or any other material on request.

St St316 (standard), St St304, 316L, Monel, Inconel, Hastelloy B/C or any other material on request

BunaN (Nitrile), Neoprene, Fluroelastomer (Viton), PTFE or any other material suitable for process / on request

Reinforced Polymers like Buna N (Nitrile), Neoprene, Fluroelastomer and PTFE

Carbon Steel IS4454 Gr.II / III, H12, EN47, SS302, SS316, Inconel X750 or any other material on request.

Fabricated Steel (Standard) and other on request.

The U200 series are pilot operated self actuated globe type medium pressure back pressure regulating valves meant to regulate the inlet pressure at pre-determined set value required for the processes/equipment protection.

Movement occurs as pressure variations register above the diaphragm of main regulator. The registering pressure is the inlet or upstream pressure. The inlet pressure acts on the diaphragm of the pilot. Pilot is an upstream pressure control valve which opens in the event of high upstream pressure than its set pressure. Rise in inlet pressure above the set pressure opens the pilot affecting the main valve to open and flow to take place. The pressure is apply on the diaphragm in main regulator through pilot valve, it pushes the diaphragm down of main regulator, an opens the port. As inlet pressure is compensated, the pilot valve get closed, diaphragm in main regulator moves up due to spring force and port opening closes.

Movement occurs as pressure variations register above the diaphragm of main regulator. The registering pressure is the inlet or upstream pressure. The inlet pressure acts on the diaphragm of the pilot. Pilot is an upstream pressure control valve which opens in the event of high upstream pressure than its set pressure. Rise in inlet pressure above the set pressure opens the pilot affecting the main valve to open and flow to take place. The pressure is apply on the diaphragm in main regulator through pilot valve, it pushes the diaphragm down of main regulator, an opens the port. As inlet pressure is compensated, the pilot valve get closed, diaphragm in main regulator moves up due to spring force and port opening closes.

FEATURES

These are designed to respond to the smallest rise in pressure at inlet and allow the excess pressure at outlet affecting protection of equipments and helping the efficiency of equipments like pumps and compressors. These are also used as Pressure Holding Valves as they hold the pressure at upstream.

This series of pressure regulating valves are self actuated or self contained and hence, do not require any external energy like pneumatic air or electricity to operate.

The impulse sensing is internal ie through the valve body itself avoiding the impulse tubing for sensing.

The inlet pressure directly acts on the diaphragm to counter balance the spring force affecting efficient response capability and accuracy.

The maintenance and inspection of the pressure regulating valve internals is possible without removing body from pipe line.

As a standard we provide trim material as AISI 316. Wide range of material is available to suit various services for different process fluids including corrosive fluids. NACE compliance can be provided for sour services.

Cap and adjusting screw discourage on-field tampering of the pressure setting.

Combination of metallic and soft seat enables the leakage class VI as per ANSI FCI 70.2.

The general replacement parts are polymer parts like Diaphragm, Soft Seat & O Rings only and thus the maintenance cost is very low.

MATERIAL OF CONSTRUCTION

CS A216 Gr WCB (standard), CF8, CF8M, Aluminium, CF3, CF3M, WC6, WC9, LCB, LCC, AlumBronze, Monel, Inconel or any other material on request.

St St316 (standard), St St304, 316L, Monel, Inconel, Hastelloy B/C or any other material on request

BunaN (Nitrile), Neoprene, Fluroelastomer (Viton), PTFE or any other material suitable for process / on request

Reinforced Polymers like Buna N (Nitrile), Neoprene, Fluroelastomer and PTFE

Carbon Steel IS4454 Gr.II / III, H12, EN47, SS302, SS316, Inconel X750 or any other material on request.

Fabricated Steel (Standard) and other on request.