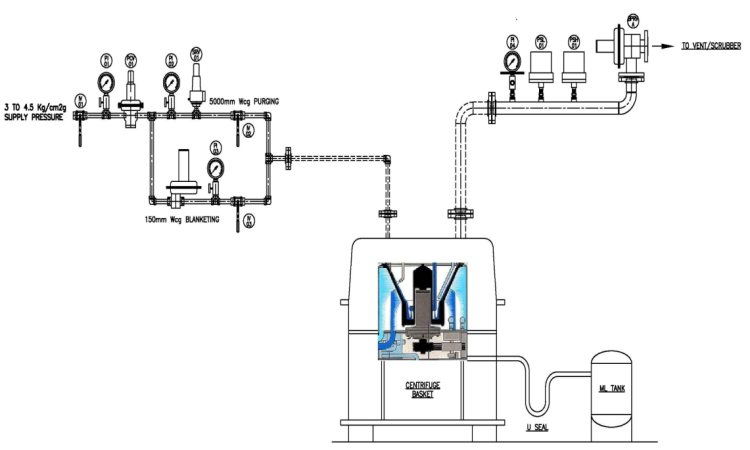

Centrifuge /Reactor Blanketing

Centrifuge Blanketing System

- One is the so called timed-volume or continuous-purge approach, in which the vessel is flushed with inert gas initially, followed by a flow of inert gas that assumes that conditions will be maintained below the Minimum Oxygen Concentration level (MOC).

- The second is a pressurised approach, in which the vessel is flushed, and then a positive pressure is maintained within the vessel with the inert gas.

Application

There is an extensive range of Centrifuge types and sizes. The most common type is the top or bottom discharge filtration batch centrifuge. Other types include the Continuous Decanter Centrifuge, the Disc Stack etc.

The types of industries using Industrial Centrifuges are similarly diverse. These include the chemical, pharmaceutical, petro-chemical and food industries. Every year a number of explosions involving Centrifuges are reported. Each time the accident enquiry pinpoints human error, equipment failure or bad engineering design as the major causes.

A typical process cycle of a batch type Centrifuge:

Centrifuge sweeping or purging with nitrogen gas, usually Nitrogen.

Feed slurry is introduced to the Centrifuge, i.e. the separation stage.

Again purge the centrifuge with the inert gas to remove the oxygen level.

Close Purging operation & start blanketing throughout spinning.

After final spinning, most of the liquid has been removed from the cake.

Final remaining solids are discharged from the basket or bowl.

During all these operations the Centrifuge must be inert either by purging or by blanketing with inert gas.

The principle behind inertizing is that if one can keep the oxygen level below the minimum oxygen level for combustion (MOC) i.e. 3 – 6% then there is zero probability for an explosion.

The System

Manual Centrifuge Blanketing System

Semi-Automated / Timer Based System

Fully Automated / On-Line Oxygen monitoring system

Brief on the Manual System

Manual Centrifuge Blanketing System

Manual Centrifuge Blanketing System is one of the most preferred system in pharma industry because of the following advantages :

User-friendly and easy to understand & operate.

Operator has to operate only two isolation valves.

Except Nitrogen no other utility required.

No special tools & tackles / expertise are required.

Minimum corrections to upgrade to Semi or Fully Automated.